LiDAR System Calibration

Group 8 Technology, Inc. (G8T) produces extrinsic calibration materials for LiDAR perception systems. These systems, operating in the Near-IR and Short-Wave Infrared (SWIR), require calibration materials that have a dynamic range of spectral reflectivity at the relevant wavelengths (frequently 905nm, 1064nm or 1550nm). The coatings applied to the Type 822 woven polyester target fabric are pigmented to be devoid of spectral structure out to 1700nm and are routinely used by LIDAR system designers as reference surfaces or calibration panels. Spectral reflectivity levels that are available at the stated wavelengths cover the same range as the portable gray scale targets, that being from less than 3% to greater than 80%.

Panels of various sizes are manufactured by G8T, the smallest generally being 1.2Meters per side. These are usually fabricated without corner grommets as most LiDAR system integrators prefer to mount the panels on a rigid substrate themselves to be deployed on their specific calibration stand. G8T also provides the coated Type 822 target fabric in roll form 1.4 meters wide by up to 25 meters (or more) long. The long rolls of Type 822 polyester fabric may be laser cut to specific sizes and shapes to satisfy specific LiDAR test objectives.

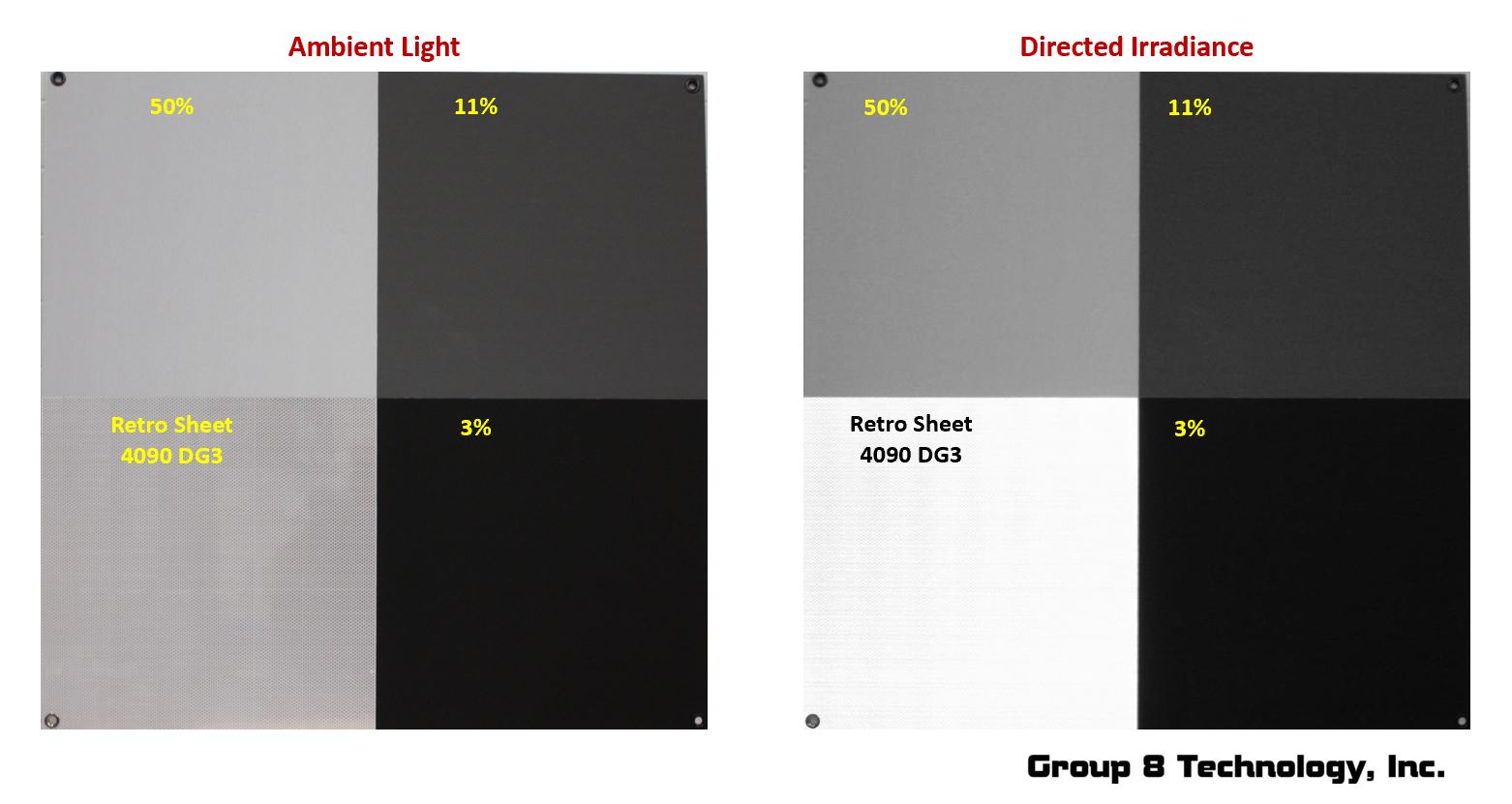

G8T has also fabricated a multilevel test panel, illustrated above, that has three gray levels along with a sheet of 3M-4090-DG3 retroreflective material to produce a high intensity return as may be encountered by a vehicle mounted LiDAR interrogating a retroreflective traffic sign. The user may specify the reflectivity levels of each grayscale step (3%, 11%, 50% illustrated above). The size of the individual levels, also illustrated above, is 0.5 meters per side giving a target panel external dimension of one meter. The sizes and shapes of the individual steps may also be specified by the user – the limit being the size and portability of the overall panel.

The target pictured above was mounted on a light-weight plastic honeycomb panel. Other substrate materials may be specified by the user. Please contact us to communicate your detailed calibration requirements and to receive a price quotation.